|

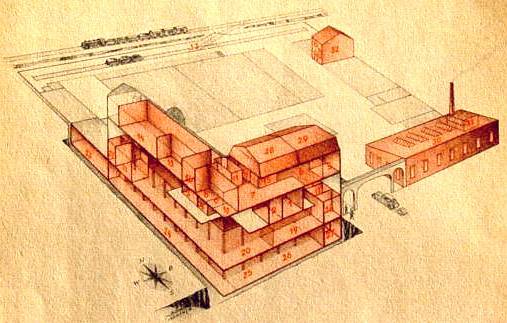

Bungartz works before World War II:

1. Works manager

2. Secretaryship

3. Management

4. Ads department

5. Chief of construction

6. Design office

7. Sales office

8. Book-keeping

9. Office management

10. Export department

11. Conference room

12. Calculation room

13. Reception

14. Staff canteen

15. Kitchen

16. Toilets and cleaning room

17. Engineering, behind that

works management

18. Door-keeper

19. Investigation department,

students' workshop,

behind that engine workshop

|

20. Assembler's workshop,

gearbox-, tiller gears-

and final assembly

21. Paint shop

22. Spraying workshop

23. Storage for raw castings and

forged iron, behind that

parts storage

24. Storage for completed parts

25. Garage,

behind that smithy

26. Welding shop, behind that

heating systems and kitchen

27. Transformer room, behind that

air conditioning and sanatory facilities

28. Showroom for models

29. Showroom for test models

30. Machinery room

31. Tempering workshop

32. Test room

33. Railway connection |

When Bungartz & Co. had been founded in 1934, they manufactured not only car trailers, but rotary tillers as well, after the designs of the engineer Josef Fey. The picture shows the Fey-Gobiet-tiller model "Schatzgräber" (treasure digger), which had previously been built from 1927 and had a 5 hp engine. As in contrast to the Siemens tillers which had spring-loaded tools, the Fey's tools were rigidly connected to the tiller axle, which last could be adjusted to start slipping at overload by means of pressure springs. Helped by the advantage of a differential in the gearbox, this construction proved very successful in forestry. By selling these Fey tillers, the Bungartz company became a feared competitor for the Siemens & Halske company, which had been in tiller manufacturing for many years. Because of internal reasons, the electronics company Siemens & Halske had to give up tiller production, and so the unlikely happened, that the smaller company bought up the bigger. Bungartz & Co. took over the production of the existing Siemens tiller K5 in August 1935. Bungartz also committed their selves to ensure the parts supply for the previously sold Siemens tillers, and took over the Siemens network of specialized dealers. The former Siemens engineer Schmidt was engaged as Bungartz's chief engineer. Constructor Josef Fey broke the contracts with Bungartz, manufacture of the Fey tillers was continued by the Meyer-Brackwede engineering-works.

When Bungartz & Co. had been founded in 1934, they manufactured not only car trailers, but rotary tillers as well, after the designs of the engineer Josef Fey. The picture shows the Fey-Gobiet-tiller model "Schatzgräber" (treasure digger), which had previously been built from 1927 and had a 5 hp engine. As in contrast to the Siemens tillers which had spring-loaded tools, the Fey's tools were rigidly connected to the tiller axle, which last could be adjusted to start slipping at overload by means of pressure springs. Helped by the advantage of a differential in the gearbox, this construction proved very successful in forestry. By selling these Fey tillers, the Bungartz company became a feared competitor for the Siemens & Halske company, which had been in tiller manufacturing for many years. Because of internal reasons, the electronics company Siemens & Halske had to give up tiller production, and so the unlikely happened, that the smaller company bought up the bigger. Bungartz & Co. took over the production of the existing Siemens tiller K5 in August 1935. Bungartz also committed their selves to ensure the parts supply for the previously sold Siemens tillers, and took over the Siemens network of specialized dealers. The former Siemens engineer Schmidt was engaged as Bungartz's chief engineer. Constructor Josef Fey broke the contracts with Bungartz, manufacture of the Fey tillers was continued by the Meyer-Brackwede engineering-works.

First own models

Firstly, Bungartz now extended the manufacturing for the Siemens tiller, and 1937 added the Bungartz L3 to this primary model, powered by a 4.5 hp DKW engine. It was meant to succeed the Swiss SIMAR tillers C2 and C3, which Siemens had formerly imported into Germany. During the next years they improved the Bungartz tiller K5, construction Siemens (stronger gearbox, wheel clutches, more powerful engine) as well as the L3 (2000 of which were sold), until eventually they developed into the models 6 hp F70 and 4.5 hp F40. As a new machine the stronger F90 was presented, with an 8.5 hp DKW engine. The increasing shortage of labourers in horticulture caused a need for a motorised cultivator besides the rotary tiller, so Bungartz developed the motorised cultivator H2 and its successor, the Bungartz H3 to fill that need.

Firstly, Bungartz now extended the manufacturing for the Siemens tiller, and 1937 added the Bungartz L3 to this primary model, powered by a 4.5 hp DKW engine. It was meant to succeed the Swiss SIMAR tillers C2 and C3, which Siemens had formerly imported into Germany. During the next years they improved the Bungartz tiller K5, construction Siemens (stronger gearbox, wheel clutches, more powerful engine) as well as the L3 (2000 of which were sold), until eventually they developed into the models 6 hp F70 and 4.5 hp F40. As a new machine the stronger F90 was presented, with an 8.5 hp DKW engine. The increasing shortage of labourers in horticulture caused a need for a motorised cultivator besides the rotary tiller, so Bungartz developed the motorised cultivator H2 and its successor, the Bungartz H3 to fill that need.

All the way from the start, Bungartz greatly valued the maximal extension of their design and research departments, in order to always be able to advertise their machinery to the customer as the best that could be obtained. The developments did not only lead to new models, but a whole series of attachments was presented, such as ploughs, pumps, mowers and cultivators. The object was not just to sell as many machines as possible, but also to advise the customer. The numerous dealers at home and abroad have always exceedingly maintained this customer service. Because of the immensely growing number of customers and the hard traveling possibilities caused by war conditions, it became desirable to contact the customers directly from the factory every now and then. To perform this, the "Bungartz-Fräsendienst" (tiller-service) in DIN-A5 size was regularly published from 1941 (the picture shows the first issue of March 1, 1941, 24 pages). This periodical reported about factory news, gave practical advice, but also gave word to the people who worked with the machinery.

All the way from the start, Bungartz greatly valued the maximal extension of their design and research departments, in order to always be able to advertise their machinery to the customer as the best that could be obtained. The developments did not only lead to new models, but a whole series of attachments was presented, such as ploughs, pumps, mowers and cultivators. The object was not just to sell as many machines as possible, but also to advise the customer. The numerous dealers at home and abroad have always exceedingly maintained this customer service. Because of the immensely growing number of customers and the hard traveling possibilities caused by war conditions, it became desirable to contact the customers directly from the factory every now and then. To perform this, the "Bungartz-Fräsendienst" (tiller-service) in DIN-A5 size was regularly published from 1941 (the picture shows the first issue of March 1, 1941, 24 pages). This periodical reported about factory news, gave practical advice, but also gave word to the people who worked with the machinery.

In spring of 1939 Mr. Johannes Sembdner, a Bungartz dealer in Germering near Munich, describes his experience with a. o. the Bungartz L3: I sold and demonstrated over 30 machines in only a couple of days! Among them were 3 customers who already bought their second Bungartz tiller, design Siemens!

No wonder, when one sees, that over 20 % of the current production of Bungartz & Co., Munich, is exported abroad. And this despite many other countries building tillers nowadays and German products are hard to sell abroad because of the severe anti-German propaganda. Products that show such fine export numbers in spite of the large competition at home and abroad, simply have to be of outstanding quality!

The latest statistics show that a 100 % of the common tiller export from Germany has been sold exclusively by the company of Bungartz & Co., Munich! This proves better than any testimony (of which I publish several from the last weeks nevertheless) the quality of the machines I supply. Only the very best can survive on the nowadays export market and that very best is exactly fit for my customers in horticulture! Bungartz tillers control the entire market. During 1938, Bungartz alone produced 84 % of the common German export of rotary tillers and small tractors, in 1939 this was even 94,5 % till now! Financially, Bungartz supplied 80,2 % of the total German sales!

During World War II

I have found no indications whatsoever that Bungartz & Co. had Nazi sympathies, but they were proud of their cultivators' contribution to the German economy in 1941. During wartime, the share of vegetables and fruits in nourishment of the people was gradually increasing, as a result of which the German growers had to raise their efforts. Despite the lack of workmen and animals the growers were able to accomplish their giant task, mainly by applying machinery for soil preparation. Many agricultural companies would have been forced to stop, like a lot of contemporary proprietors confirmed to machinery dealers. "Thousands of Bungartz tillers will perform their most blessed labour in food supply, for the good of their owners and of the entire German people. Bungartz leads in Germany as well as in exports. Thus, the supply of German quality products abroad helps the German economy, by both yielding foreign exchange and important imported products."

I have found no indications whatsoever that Bungartz & Co. had Nazi sympathies, but they were proud of their cultivators' contribution to the German economy in 1941. During wartime, the share of vegetables and fruits in nourishment of the people was gradually increasing, as a result of which the German growers had to raise their efforts. Despite the lack of workmen and animals the growers were able to accomplish their giant task, mainly by applying machinery for soil preparation. Many agricultural companies would have been forced to stop, like a lot of contemporary proprietors confirmed to machinery dealers. "Thousands of Bungartz tillers will perform their most blessed labour in food supply, for the good of their owners and of the entire German people. Bungartz leads in Germany as well as in exports. Thus, the supply of German quality products abroad helps the German economy, by both yielding foreign exchange and important imported products."

Sales numbers of Bungartz tillers show that they did not stop selling during the Second World War:

| until 1940 | 5000 |

| until 1942 | 10.000 |

| until 1945 | 35.000 |

The Bungartz factory in Munich suffered a lot from the allied bombings during World War II. These pictures show the re-erection of the demolished buildings in 1944:

With a small crew of employees, but with a wealth of experience, the destructed factory buildings were rebuilt. Already in 1945, they supplied the first rotary tillers, which were manufactured between the remains of ruins and ashes. A large advantage in getting assigned enough raw material, was that the Bungartz tillers were not fit for military purposes.

In 1953 Bungartz & Co. again had around 350 employees. From 1945 till 1953 they supplied 8000 weed tillers as well as 11,500 walk behind tractors, 20 % of which had still been manufactured by contract suppliers. The large demand after Bungartz tillers was mainly caused by the application of high-quality materials and by the good isolation of the machines' interior against dirt and dust.

Large walk behind tractors

The engineering department did not hesitate to grab the occasion with both hands. Bungartz needed a replacement for the large tiller F90, which had been become available with the 10.5 hp Ilo engine after the war. This tractor was actually only applicable with the rotary tiller attachment, but the gardeners needed a tractor that was able to do more different jobs. Against the end of the 1940s the walk behind tractor Bungartz U1 was presented, for which Bungartz produced almost everything their selves, ranging from the 11 hp Bungartz paraffin engine over the gearbox until the mower attachment. But the tractor was also available with the 10.5 hp Ilo petrol or paraffin engine, and with the 14 hp Stihl diesel engine. The U1 was very widely employable: the available attachments enabled the growers to perform 25 different duties, and thus it replaced 15 other machines.

As the U1's successor, the Bungartz L5 was offered from 1953, from the start powered by the same Bungartz or Stihl engines as the U1 had had. But the L5 gained real success by the application of the 10 or 12 Sachs two stroke diesel engines (developed by Max Holder), and the 13 hp Hatz four stroke diesel engine. The L5 had more gears than the U1, and unlike its predecessor, also standard had a lockable differential in its gearbox. The outstanding quality of the Bungartz L5 may become clear from the fact that it remained available until 1969!

In cooperation with the company of Hummel in Heitersheim (Germany), a trailer was developed of which the wheels were driven by the walk behind tractor's PTO. With this trailer after the tractor, a four-wheel drive vehicle came into existence, which had the advantage that the trailer's cargo contributed to the tractive power.

Of course, the own Bungartz trailers were still made as well. At least until the war Bungartz manufactured car trailers, the trailers for use with walk behind and four-wheel tractors were constantly under development and remained available in many different variations until deep into the sixties.

Small walk behind tractors

As a replacement for the weeds tiller H2, the Bungartz H3 was presented in 1940. At first it was powered by 2 or 3 hp Sachs petrol engines, after the end of the was with the 4 hp TWN engine (Triumph Werke Nürnberg). Of the H3 alone, 5000 were made until 1945, and 8000 until 1954. From 1954 it was succeeded by the H3N model, powered by a 4 hp Sachs Stamo 160 engine.

Meanwhile, the medium weight two-wheel tiller F40 had been evolved into the Bungartz F55 and FR, the latter of which was equipped with two forward and two reverse gears, as well as optional steering clutches. Both models were available with 6 hp TWN engine, the FR also with a 6 hp Ilo two stroke, or Universal four stroke engine. The Universal engine was purchased from the company Alfred Berning Motorenbau in Schwelm (Westfalen, Germany), who produced these petrol engines as licensee of the Swiss company Universal.

The growers needed more application possibilities in this model range as well. Therefore, in 1953 the Bungartz H4 was introduced, a tractor with four forward and two reverse speeds. There seemed to have been put incredibly many possibilities into this relatively small gearbox. The application of the patented Bungartz quick-action coupling simplified switching between attachments. It was powered by a 5 hp petrol engine, at first from TWN (H4 series 1), later from Fichtel & Sachs (H4 series 2, 3 and 4). The H4 had a long range of successors, each of which had more possibilities hidden into the gearbox, whose form almost remained unchanged:

FRN (series 4) in 1955 and 1956, 6 - 7.5 hp Sachs petrol engine, 4 forward and 2 reverse gears.

H5 (series 5) from 1957 till 1959, this was a cheaper version of the FRN, with just a 5 hp engine.

FRK and FRNK (series 5), made from 1957 till 1959, 6 forward and 2 reverse speeds, petrol or diesel engine.

FRNK (series 6 and 7), 1959 till 1961, standard with lockable differential, petrol or diesel engines.

H5 (series 6 and 7), 1959 till 1961, 7.5 hp Sachs petrol engine, gearbox without differential and low gearing (so 3+1 gears).

Of course, all of this had transformed the Bungartz FRNK into a medium weight class walk behind tractor.

Medium weight walk behind tractors

When the constructors also wished to have a gear independent PTO for the new Bungartz FK (series 8) from 1961, they were eventually forced to develop an entirely new gearbox housing. This gearbox had a mechanically delicate construction with 4 forward and 3 reverse speeds, as well as full differential and a steering clutch on both sides, later even extended with steering brakes. The FK was available with two or four stroke petrol and diesel engines ranging from 8 up to 10 hp. The most successful version was the one with the 8 hp Berning four stroke diesel engine, made by Alfred Berning in Schwelm.

Apparently, part of the clientele felt that the Bungartz FK was too complicated, and therefore too expensive. That is why Bungartz presented the Bungartz H6 in 1963, available as model Bungartz F6. Again, this tractor had a completely new gearbox, this time very much simplified and with conical gears instead of the regular worm wheel transmission. This machine was equipped was 3 forward and 1 reverse gears, and only single side steering clutch. The speeds were perfectly chosen for tilling, ploughing as well as transport work. For transporting purposes there were wheel brakes available for both sides, besides the standard internal transmission brake. The F6 again was available with a large range of different engines in order to fit every customer's wishes. There was the Sachs two stroke engine, as well as the 9 hp strong BMW Industriemotor model 403 (an adaption from BMW's Isetta engine). But the F6 is most common equipped with the 7 hp four stroke diesel engine E79 from the Hatz company in Ruhstorf (Germany). The quality of the Bungartz F6 was confirmed by the fact that it remained available for almost 30 years, and that it still is much looked for nowadays.

Four-wheel tractors

In 1953 Bungartz entered the four-wheel tractor market with the prototypes T1 and T2, constructed by Mr. Koppmair. The tiller tractor Bungartz T3 was presented on the DLG-exhibition in Cologne, being a continued development from the walk behind tractor U1. The T3 was available with either the own 11 hp petrol/paraffin engine or the 14 hp Stihl diesel engine. Narrow track, 6 speed gearbox and an interesting range of attachments were applicable. Very special were the T3's automatically engaging steering brakes when the steering wheel was turned towards the end.

More successful than the T3 was the Bungartz T5, now based on the walk behind tractor L5, with 12 - 13 hp engines and introduced in 1956. Unfortunately, it came just at a time that the German market for agricultural tractors dramatically collapsed. The T5 had certainly not been developed for use at every farm, but instead as a special tractor for intensive row crop as well as for maintenance jobs. Thus, Bungartz stayed closely attached to the large-scale horticulture, which had always been purchasing a lot of walk behind tractors as well. This was also clear from the technical features: narrow track, fit for use on slopes, engine powered hydraulics, well thought-out transmission, it was very manoeuvrable by use of the smallest possible turning radius, this completed with a range of attachments such as rotary tillers, irrigation pump and compressed air hammer; all of this showed that Bungartz had created something special with the T5. Also noteworthy is the patented 90-degree steering. This enabled the wheels to turn almost squarely, which, assisted by the oversized steering brakes, allowed a turn around one of the rear wheels.

New Bungartz factory

Bungartz & Co.'s main business was still the development of rotating soil cultivating tools. These implements are applicable everywhere, where soil rich of vegetable mold is available for intensive growing, so specifically in horticulture. Besides, this way of cultivating the soil is very suitable for forestry, fruits growing and winery. Soil cultivation with rotating tools is also of special interest in hot areas, like the area around the Mediterranean, in southern Africa and in Central and Latin America. Under the local conditions in those areas, rotary soil cultivation is anyway only possible with very rigid implements. This is the reason that Bungartz & Co. had an export share of over 40 % in 1958. They controlled the Mediterranean area with their tractors and special attachments, and besides of that the machinery was sold in over 60 countries around the world.

Bungartz & Co.'s main business was still the development of rotating soil cultivating tools. These implements are applicable everywhere, where soil rich of vegetable mold is available for intensive growing, so specifically in horticulture. Besides, this way of cultivating the soil is very suitable for forestry, fruits growing and winery. Soil cultivation with rotating tools is also of special interest in hot areas, like the area around the Mediterranean, in southern Africa and in Central and Latin America. Under the local conditions in those areas, rotary soil cultivation is anyway only possible with very rigid implements. This is the reason that Bungartz & Co. had an export share of over 40 % in 1958. They controlled the Mediterranean area with their tractors and special attachments, and besides of that the machinery was sold in over 60 countries around the world.

The increasing activities obliged an extension of the factory buildings, which could be put into use in the beginning of 1958. On the Neumarkter Straße a very modern factory with fitting offices, exhibition, customer care and storage buildings was erected. At that time, the company employed over 320 technicians, managers and pupils. Against 1958, Bungartz & Co. had been producing over 36,000 tractors of variable size and nature. Because Siemens tillers were made prior to that, the machines produced by Siemens & Halske can be added to Bungartz's experience, so that it can be stated that Bungartz & Co. at that time had the experience of building approximately 50,000 tractors and rotary tillers.

Bungartz & Co. had been paying 14.3 million Marks on wages and salaries up to 1958. During this period the proceeds of social security (employer's share) was 2.1 million Marks and another 2.1 million Marks of income-tax. So Bungartz & Co.'s activities had contributed a total amount of 18.5 million Marks to the Bavarian economy until 1958.

Left: The new factory's entrance.

Right: View into a factory building, where tillers are being produced on the assembly line.

The value of the new buildings on the Neumarkter Straße amounted to 1.85 million Marks, including costs of land. Another 1.8 million was invested on machinery and implements. The raising sales in walk behind tractor industry (as opposed to the four-wheel tractor industry) and the extension of the Bungartz & Co. sales organisation resulted in a net turnover of over 8 million Marks during 1957.

Bungartz abroad

In the Netherlands the Bungartz tillers were imported by the Dilling & Rokahr company in Rotterdam. After World War II this was adopted by the Agincore NV company in Amsterdam, later Diemen, which had been specially formed to perform this task. They were very successful in distributing the Bungartz tillers, and later tractors, to the Dutch growers. The importer for Belgium was the company of Edmond Isbeque in Brussels / Schaarbeek. However, Bungartz tillers were also sold in France, Bungartz licensed the French Ellecinque company to produce them as well.

Mainly Bungartz four-wheel tractors were supplied to the USA, most of them being the model T5. These were distributed by the sole importers for Canada and the USA, Burton Supply Co., Inc. in Youngstown, Ohio. They had subsidiaries in Columbus (Ohio), Dunkirk (Ohio), Bedford (Pennsylvania) and Harrisburg (Pensylvania).

Mainly Bungartz four-wheel tractors were supplied to the USA, most of them being the model T5. These were distributed by the sole importers for Canada and the USA, Burton Supply Co., Inc. in Youngstown, Ohio. They had subsidiaries in Columbus (Ohio), Dunkirk (Ohio), Bedford (Pennsylvania) and Harrisburg (Pensylvania).

Also at least one weed tiller model H1 survived in the USA, supplied by the "Universal Tractor Corp., US representatives for Maschinenfabrik Bungartz, Germany", 50 Broad Street, New York. Besides, the Bungartz FRN and L5 models were even available with Wisconsin engines!

Not very successful was Bungartz's effort to start a license manufacture of the Bungartz T5 tractor by the AGRISA company in Brazil, together with engine manufacturer Hatz of Ruhstorf, Germany. They did produce at least some Bungartz L5 with Hatz engine.

New products

The increased capacity of the new Bungartz factory was partly used for extending the tractor production. Thus, to the now 13 hp strong T5, the 20 hp Bungartz T6 was added. This tractor, powered by a twin cylinder MWM diesel engine and equipped with a 6+1 speeds Hurth gearbox, had the distinctive feature of an extra PTO under the tractor, for direct drive of a side-fitted mowing bar. It was not long until the Bungartz T7 with 34 hp Volkswagen Industriemotor, later also available with 20 hp MWM engine, was presented. The T7's Bungartz made transmission was identical with the T5 model, the difference between the models was just the engine power.

Bungartz introduced the successor for the H3N in 1959: the Bungartz H1 was the first one wheel weed tiller from the Munich factory. Powered by a 2.5, later 4 hp Sachs petrol engine, around 5500 of these weed tillers could be sold until 1968. Against the end of production, it was also available with a 6 hp Ilo engine. By using only one, engine driven, wheel, unlike all previous models which had two wheels, Bungartz specifically enhanced the employment for weed control in row crops.

Half way down the sixties, growers demanded smaller tractors. Therefore, Bungartz developed a narrower version of the T5 and de T7 tractors, named Bungartz T5E and T7E respectively, of which the maximum width was only 73 cm. These tractors were powered by 13 or 16 hp Hatz diesel, or 29 hp VW petrol engines. They could go even smaller: the Bungartz T4, based on walk behind tractor F6, was equipped with a 7 hp Hatz diesel engine and had 3 forward and 1 reverse gears. The hydraulic lift could be engaged by means of a hand powered pump. The T4 was mainly employed for tilling, spading and transportation in Dutch glasshouses.

Moving on together

Sales were not too bad at all for Bungartz, but it simply would not be over 300 new tractors per year. Without any doubt, this number was too low to compensate the ceasing rotary tiller production in some degree. Only outsiders were surprised, when Bungartz announced in 1965 that they had sold a large part of their Munich factory buildings to shock absorber manufacturer Boge GmbH.

Sales were not too bad at all for Bungartz, but it simply would not be over 300 new tractors per year. Without any doubt, this number was too low to compensate the ceasing rotary tiller production in some degree. Only outsiders were surprised, when Bungartz announced in 1965 that they had sold a large part of their Munich factory buildings to shock absorber manufacturer Boge GmbH.

That sales' revenue was sufficient to continue four-wheel tractor production for a while. Then construction equipment manufacturer Karl Peschke from Zweibrücken (Germany) offered to form a partnership. Peschke had been experimenting with their three wheeled PEKAZETT slope tractor UF 260, in order to enter the technically interesting field of specialist forestry tractors. Still in 1965, Bungartz and Peschke agreed to form common engineering-works, which had to erase new factory buildings in Hornbach (Saarland, Germany). In the middle of 1966 things had come to such a pass that the entire known Bungartz production, existing of one-wheel cultivators, walk behind tractors and special four-wheel tractors with between 8 and 40 hp engine power, were marketed in enhanced versions under the new brand name "Bungartz & Peschke".

That sales' revenue was sufficient to continue four-wheel tractor production for a while. Then construction equipment manufacturer Karl Peschke from Zweibrücken (Germany) offered to form a partnership. Peschke had been experimenting with their three wheeled PEKAZETT slope tractor UF 260, in order to enter the technically interesting field of specialist forestry tractors. Still in 1965, Bungartz and Peschke agreed to form common engineering-works, which had to erase new factory buildings in Hornbach (Saarland, Germany). In the middle of 1966 things had come to such a pass that the entire known Bungartz production, existing of one-wheel cultivators, walk behind tractors and special four-wheel tractors with between 8 and 40 hp engine power, were marketed in enhanced versions under the new brand name "Bungartz & Peschke".

Modern insights in industrial organization and architecture defined the construction of large-scale buildings for the production of Bungartz tractors on the Hornbach industrial estate. All assembly departments, technical offices and management were brought together under the same roof. The good internal lay-out as well as the winding up of material flows and the order of proceedings resulted in an efficient and clear arrangement of the various departments. These targets are visual on the Hornbach factory photographs. The factory setup and the technical engineering possibilities in Hornbach, together with the sister-company's metal foundry and sheet-iron factory in Zweibrücken formed a large production capacity, which was able to continue the Bungartz tradition.

Modern insights in industrial organization and architecture defined the construction of large-scale buildings for the production of Bungartz tractors on the Hornbach industrial estate. All assembly departments, technical offices and management were brought together under the same roof. The good internal lay-out as well as the winding up of material flows and the order of proceedings resulted in an efficient and clear arrangement of the various departments. These targets are visual on the Hornbach factory photographs. The factory setup and the technical engineering possibilities in Hornbach, together with the sister-company's metal foundry and sheet-iron factory in Zweibrücken formed a large production capacity, which was able to continue the Bungartz tradition.

Against the end of the sixties the four-wheel driven narrow track tractor Bungartz T8DA with 30 hp Deutz diesel engine, as well as the even stronger Bungartz T9 with 52 hp Hatz or Deutz engine, acquired many friends in the German areas with intensive hop, wine and vegetable growing.

The Bungartz T8DA was based on the Dexheimer Allrad 222, which was manufactured by the Maschinenfabrik Dexheimer GmbH in Wallertheim (Germany). Dexheimer developed the Allrad 222 in 1965. Dexheimer had a license concerning the position of the front axle, which was fitted in an 8 degree angle in order to achieve a maximum steering angle. Bungartz used the identical construction and this caused a conflict between Bungartz and Dexheimer. Dexheimer then sold a manufacturing license to Bungartz. Dexheimer still manufactured garden tractors until the start of 2014.

The T8 and T9 helped Bungartz & Peschke to achieve their best sales ever in 1969, with 459 new tractors sold. But after that, the sales numbers quickly sank to an unsatisfying level again.

From 1968, Bungartz & Peschke offered the Bungartz Kommutrac as THE solution for all sorts of activities that occurred at municipal works. For this tractor, they did not rebuild or adapt anything existing, but they created this multifunctional system unit all the way from the bottom. The vehicle was developed to carry out all maintenance work in pleasure and sports grounds as well as all road maintenance during winter time. It was able to lift and power attachments by means of its standardized connections at the front, middle and rear, and was equipped with ample hydraulics. Very interesting was the Duo-control with duplicate pedals, duplicate steering and its comfortable driver's seat which could be turned 180 degrees around. The Hurth tractor gearbox had 6 forward and 6 reverse gears, reversible in both directions, the engine was the 40 hp VW-Industriemotor (industrial engine). Available extras were front hitch, front PTO, all-wheel drive, cabin and Hatz diesel engine. The Kommutrac remained available until the end, with many special attachments. After Gutbrod acquired Bungartz & Peschke, they continued development of the tractor and it was sold as Gutbrod Kommutrac.

From 1968, Bungartz & Peschke offered the Bungartz Kommutrac as THE solution for all sorts of activities that occurred at municipal works. For this tractor, they did not rebuild or adapt anything existing, but they created this multifunctional system unit all the way from the bottom. The vehicle was developed to carry out all maintenance work in pleasure and sports grounds as well as all road maintenance during winter time. It was able to lift and power attachments by means of its standardized connections at the front, middle and rear, and was equipped with ample hydraulics. Very interesting was the Duo-control with duplicate pedals, duplicate steering and its comfortable driver's seat which could be turned 180 degrees around. The Hurth tractor gearbox had 6 forward and 6 reverse gears, reversible in both directions, the engine was the 40 hp VW-Industriemotor (industrial engine). Available extras were front hitch, front PTO, all-wheel drive, cabin and Hatz diesel engine. The Kommutrac remained available until the end, with many special attachments. After Gutbrod acquired Bungartz & Peschke, they continued development of the tractor and it was sold as Gutbrod Kommutrac.

End of a success story

With the sale of the range of tractors for municipal works and for winery to the Gutbrod company of Saarbrücken-Bübingen in 1974, there came an end to the Bungartz era in German tractor building. Their great contribution existed not so much of selling large numbers of tractors, but more of their constant development of tractors for special purposes. The Gutbrod company continued building the T8, T9 and Kommutrac for some time their selves and developed newer horticultural tractors from them. The company of Karl Peschke also kept making the Kommutrac, as well as the F6 walk behind tractor. In 1976, the Gutbrod company eventually acquired the Hornbach factory buildings their selves, and transformed them into a modern lawn mower factory.

The firm of Bungartz & Co. was founded and led by Dr. Everhard Bungartz, whose commercial vision enabled him during over a quarter of a century to develope a relatively small company into a company with world fame, which was acknowledged by abroad competitors even during difficult times. In the course of 40 years, they constructed 30 different tractor models, and besides that over 50 models of motorized cultivators and walk behind tractors. Dr. Bungartz died in 1984.

Today (2003) it is hard to find any remains of the Bungartz & Peschke company in Hornbach. In Gutbrod Street is the factory building, where Gutbrod and MTD mowers rolled off the production line. Since 2006, MTD uses the entire building as a central spare parts warehouse (until then housed in the headquarters in Saarbrücken) for all customers in Europe, Africa and Russia. 50 Employees work at the site permanently; seasonally even up to 75. Hornbach's central location in the heart of Europe enables MTD to supply all major markets within 24-48 hours. In addition, since the year 2011 also the new after-sales brand ARNOLD was fully integrated at the site Hornbach as a cross-industry spare parts specialist with a private assembly centre, see www.arnoldproducts.eu or MTD after-sales video with a complete tour through the warehouse.

Today (2003) it is hard to find any remains of the Bungartz & Peschke company in Hornbach. In Gutbrod Street is the factory building, where Gutbrod and MTD mowers rolled off the production line. Since 2006, MTD uses the entire building as a central spare parts warehouse (until then housed in the headquarters in Saarbrücken) for all customers in Europe, Africa and Russia. 50 Employees work at the site permanently; seasonally even up to 75. Hornbach's central location in the heart of Europe enables MTD to supply all major markets within 24-48 hours. In addition, since the year 2011 also the new after-sales brand ARNOLD was fully integrated at the site Hornbach as a cross-industry spare parts specialist with a private assembly centre, see www.arnoldproducts.eu or MTD after-sales video with a complete tour through the warehouse.

The PEKAZETT (PKZ = Peschke Karl Zweibrücken) cranes are still being manufactured today by KSD Kransysteme GmbH in Zweibrücken.

Holter Maschinenhandel

On June 1, 1974, Mr. Josef Bachmair acquired the complete stock of Bungartz & Peschke spare parts, for his Holter Maschinenhandel in Schloß Holte-Stukenbrock. Mr. Bachmair, who was born in 1926, started as a salesman student at Bungartz in München in 1941. He has been in the machinery business ever since: from 1941 in the technical office service, from 1955 till 1969 in field service. January 1st, 1970, he started his own Holter Maschinenhandel, and acquired the dealership for the Bungartz & Peschke factory, as well as for many other brands as time passed by. Until 1992, the HMH still produced the Bungartz F6. The company still has many Bungartz parts in stock, or can even have them remanufactured.

On June 1, 1974, Mr. Josef Bachmair acquired the complete stock of Bungartz & Peschke spare parts, for his Holter Maschinenhandel in Schloß Holte-Stukenbrock. Mr. Bachmair, who was born in 1926, started as a salesman student at Bungartz in München in 1941. He has been in the machinery business ever since: from 1941 in the technical office service, from 1955 till 1969 in field service. January 1st, 1970, he started his own Holter Maschinenhandel, and acquired the dealership for the Bungartz & Peschke factory, as well as for many other brands as time passed by. Until 1992, the HMH still produced the Bungartz F6. The company still has many Bungartz parts in stock, or can even have them remanufactured.

|